HOME > SERVICES> SERVICE> Types of screens

Types of screens

2005-12-26

The important parameters of projection screens and the technology and types of screens are mutually penetrating, promoting, and unique in style. Therefore, we will introduce the types of screens along the technical context below.

Shadow screens are mainly divided into front projection screens and back projection screens according to the projection method;

Projection screens are divided into hard screens and soft screens based on the material of the screen;

Screens are divided into different application modes: electric, manual, frame, embedded wall, and bracket;

Screens are classified according to their different surfaces: Fresnel optical screens, diffuse reflection optical screens;

The general technology of screens: The key to screen technology is to use the materials on the screen surface to solve the scattering, reflection, and refraction of light, and to correctly solve and improve the corresponding three parameters, which is the theme of screen technology. Below, we will provide an explanation of screen technology and types from two main categories: front projection screens and rear projection screens. Regardless of the application method, the main technology of positive projection soft screens is to spray various materials on a non transparent fabric surface. Different optical materials are used in the surface materials, and the optical factor (commonly known as glass beads in China) and quality of the optical materials determine the viewing angle, surface gain, and other important parameters of the screen. Figure 1.3.1a/b reflects the optimization effect of glass beads on projection light under ideal conditions. The stability and uniformity of surface spraying optical factors affect the quality of screen images.

The material of the rear projection soft screen is PVC, which also requires processing of the screen surface material and screen material. The projection light shines onto the screen from the back and forms an image. The optical factors on the screen surface optimize projection optics, improve image quality, and determine the gain, viewing angle, and resolution of the screen based on the amount and distribution of optical factors. The optical factors and other pigments on the screen surface can optimize the color saturation and image of the projected image. The types and technologies of hard screens are mainly diffuse reflective optical hard screens and Fresnel lens optical screens.

1. Diffuse reflection screen

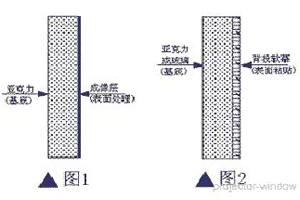

The origin of diffuse reflection screen technology is relatively early, but its early development was slow. In recent years, with the expansion of application scope, it has developed rapidly. Its main characteristics are: large viewing angle, low gain, strong ability to capture ambient light, and wide application range. 1) One of the technologies for diffuse reflection screens is to directly process and produce acrylic surfaces. As shown in Figure 1, the screen viewing angle and clarity are not ideal, and the solar effect is also quite severe. Mainly based on the manufacturing methods of domestic manufacturers. 2) The second technology of diffuse reflection screens is to use transparent materials such as acrylic and glass as substrates, and paste a back projection soft screen on their surface to make it. As shown in Figure 2, this technology has been maturely applied in various industries, with a 180 degree viewing angle from top, bottom, left, and right, and no solar effect. At the same time, the screen size is relatively large.

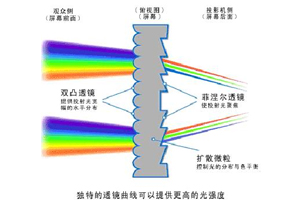

2 Fresnel lens optical screens

A Fresnel optical lens screen has patterns on both the front and back surfaces of the screen, concentric Fresnel lens patterns on the surface facing the projector, and vertical stripes on the surface facing the audience with biconvex (cylindrical) lenses. The different patterns on both sides optimize the optical performance of the projector, greatly increasing the screen's gain. However, the vertical viewing angle of the screen is severely affected. At present, internationally renowned manufacturers mainly include STEWART Screen Company (manufactured in the United States), DNP Printing Company (manufactured in Denmark), and SVS Screen Company (manufactured in Denmark). Fresnel optical lens screens have different focal lengths depending on the angle of the Fresnel lens slot, in order to meet the needs of different lens projectors. The principle of a Fresnel optical lens screen is illustrated above. The characteristics of Fresnel optical screens are closely related to the biconvex lens pitch and Fresnel lens slot distance of the screen. At present, the Fresnel slot spacing of the screen mainly ranges from 0.1 to 0.5 millimeters, and the convex lens pitch is mainly from 0.2 to 0.8 millimeters. Each manufacturer has clear indicators based on the size of the screen. The gain of Fresnel screens is relatively large, ranging from 2.0-12, and can be selected according to different usage environments. Meanwhile, due to the small lens slot spacing on the screen surface, different manufacturers use different materials and processes, resulting in inconsistent surface hardness of the screen, which will directly affect the use and maintenance of the screen.

3. Other rear projection screens, as well as some rear projection screens that are processed through different technologies and used in different occasions, such as Holo screens, are used for showcase display. In addition, some short focal length double-layer screens specifically used in rear projection boxes, and in principle, screens that use short focal wide-angle lenses must completely overcome the solar effect. A better method is to align the Fresnel screens for the best effect. At the same time, some companies produce ultra short focus projection screens that add some black glass beads (pigments) in the middle of the double-layer screen to improve their resistance to ambient light, and are applied to some ultra short focus wide-angle lens projectors.

(reprinted)

更多案例

- Kedi Intelligent Three Choice for Lhasa Integrated Media Center Launch Station

- Kedi's high-definition and multi format mixed matrix has made a name for itself in the Fuzhou Municipal Party Committee

- Kedi's products have successfully passed the acceptance of the Taishan Nuclear Power Plant project

- Kedi emergency switch stationed at Ningbo Radio and Television Station

- Kedi high-definition multi format matrix for Taipingling Nuclear Power Plant

- Kedi 72 Road 4K60 Matrix for Unicom Tianjin Branch Conference Upgrade and Expansion Project

- Kedi Multi format Matrix Used in Hefei Civil Defense Ground Command Center

- The successful application of Kedi Mixed Moment in the Emergency Command Center of Mianyang Fire Brigade

- Kedi Hybrid Assists the Consultation System of Zhejiang Provincial Department of Natural Resources

- Kedi Multi format Mixed Matrix for Guangdong Provincial Emergency Department